How It’s Made – Neumann U87

Thursday, January 22nd, 2009 | by matthew mcglynn

The crew from the Discovery Channel’s “How It’s Made” show got a tour of the Sennheiser/Neumann factory in Wennebostel, and put together a 5-minute broadcast featuring the manufacture of a Neumann U87Ai  microphone.

microphone.

I was especially intrigued to see this, because I toured the same factory last April, and like the Discovery team, was able to watch a U87 being made, from the lathes cutting body parts to the clean room staff assembling capsules, to the final assembly, sweep testing, and packaging. Read more about my Sennheiser/Neumann Factory Tour.

Here’s the How It’s Made video… and below that, the transcript.

Transcript of Neumann Microphone segment from How It’s Made:

People have been doing mic checks since 1876, when the microphone was invented as part of the telephone. Microphones convert sound to a signal that can be transmitted through televisions, radios, and many other things. If you have something to say, you’ll need a microphone to broadcast it.

From the glory days of radio, to stage and screen and the digital age, the microphone has been at the center of it all.

To make a broadcast-quality microphone, they start with a support piece for it. Automated tools carve a brass cylinder to the desired dimensions. They also make a retainer ring for the microphone grille that will anchor the microphone’s metal mesh. They layer three sheets of mesh and align them; then they solder the three sheets together. A punch press forms the soldered sheets into a concave shape. They lower a blade to slice the shaped mesh in half. The two pieces will be used to make one microphone grille.

An assembler squeezes solder paste into a groove in the brass ring. Then he presses the grille halves, which have been joined by a bracket, into the solder-coated ring. On a carousel, a torch heats the rings, and the solder paste melts to bond the grilles to the rings.

A drill punctures a brass disk up to 90 times, to make ventilation holes. Another tool levels the surface and shaves off unwanted bits. This disk will be the backplate for one of the microphone’s capsules.

An assembler brushes away any remaining shavings and fixes the backplate in a holding device.

This plastic membrane has been coated with real gold to conduct electricity. She places the membrane and a plastic ring on the backplate, and then attaches an electrical lead.

She screws the plastic ring down to secure the assembly, and then trims away the excess plastic membrane. This microphone capsule is now complete.

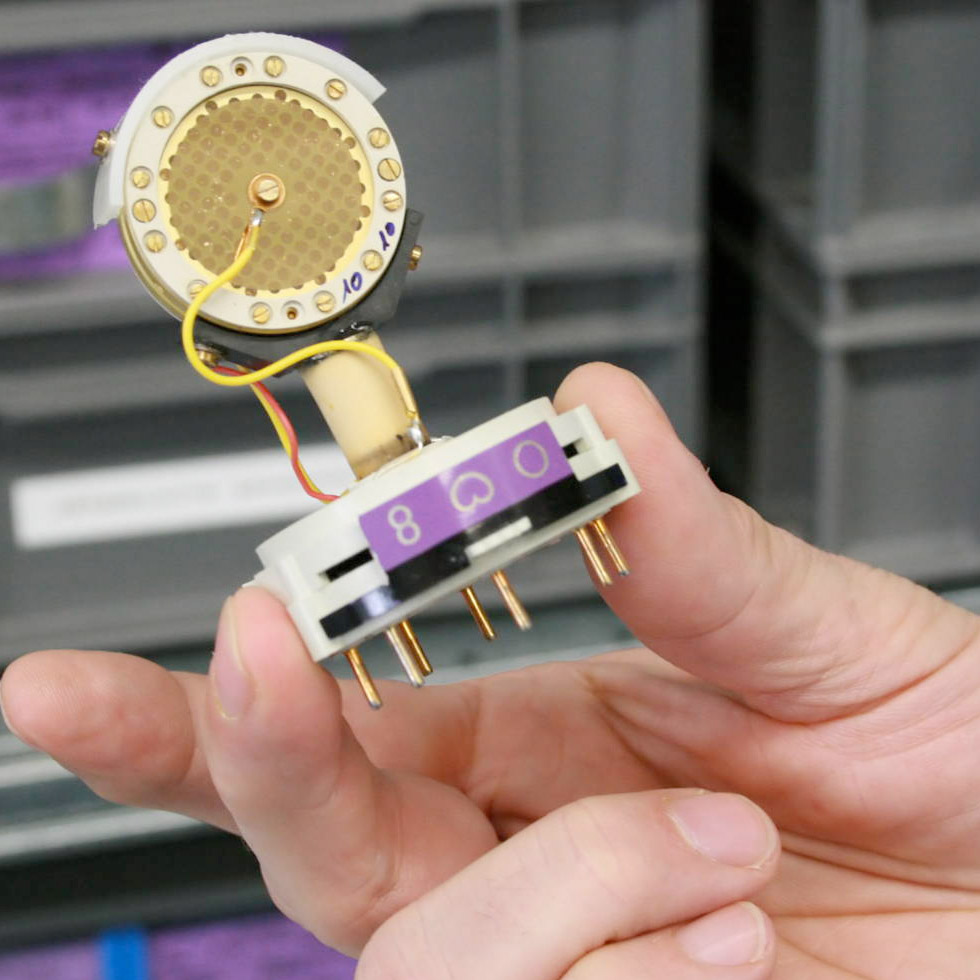

Next, she’ll join two capsules to create the unit that is the heart of the microphone. It converts sound into an electrical signal. An aluminum spacer goes between the two capsules, which face back to back.

Two capsules instead of one means this microphone can be switched to pick up audio from various directions.

A plastic bracket reinforces the assembly. A technician then wires the brass support piece that we saw being made earlier to the electronics system, and then he secures it with screws.

After installing switches, he inserts the microphone capsules in the grille. He screws the capsule assembly to the grille, and joins it to the electronics. He slides the metal casing over the electronics and secures the microphone with a big screw cap.

He checks the switch that changes the directionality of the mic. And now it’s ready for a soundcheck.

The mic goes into a special anechoic chamber. A computer measures its response to various audio frequencies and directions.

Once a microphone has passed this test and some other checks, it’s time to pack it up with great care. Because this mic is delicate and worth several thousand dollars.

Treated properly, this microphone should last several decades. In show biz, that’s longevity.

Tags: neumann, wennebostel

Posted in Microphones, Video | 9 Comments »

dave thomas

April 8th, 2013 at 12:16 pm

Hi Matthew, this still doesn’t explain why the microphones cost so damn much to the end user???

Its affordable for broadcasters with deep pockets but poor engineers, musicians and producers…not so much!!!

Cheers, Dave

http://www.aamicrophones.com

John Chase

July 31st, 2013 at 6:33 am

“Hi Matthew, this still doesn’t explain why the microphones cost so damn much to the end user???”

Sure it does!

Neumann uses the very finest parts, most hardware componentry made right in house by folks who are paid more than $15 a week, and in a facility that must conform to government safety standards.

Then there is property tax, government tax, insurance, etc., none of which is subsidized.

The machinery is expensive, high precision and costly to maintain to a high level of accuracy for day to day, year to year repeatability.

Do lesser quality microphones sound good?

Sure, many do and are quite worthy.

Are the high cost microphones worth the extra cost?

Absolutely!!

I only wish I could afford lots more Neumanns than I have, so,e DPAs, some schoepps, some Earthworks, some specialty Sennheisers to go with the ones I do have etc.

My collection began in the early 80s so I have quite a few very nice mics, but I wish I had more, and more specific special ones!

I passed up a matched pair of B&K 4011 from B&K for $500.00.

It was the first year they came to America, at the AES show and I had never seen such funny looking mics.

I only had $700.00 or so with me and that would have been nearly my total budget for the weekend, so I passed.

What a fool I was! Lol

Thank you for the “How It’s Made Article” folks.

John Chase

Brian Marten

January 26th, 2014 at 8:41 am

Great Dave, but you neglected to mention that your company, which is in direct competition with Neumann, makes your product in CHINA. I can believe that your prices are half of Neumann’s and you are still making good money. But then again, you don’t have to pay German wages.

Neumann have to make sure that their workers can make a living like the people that actually use their products. The people that make your products are not even on the same continent as you or your users.

Please, be honest about the intent and focus of your comments when you post on blogs and forums like this one.

Plus, I have seen the difference between German products and their Chinese clones. The original teknik, cars or microphones or whatever, is always better executed. If not, then why name the clones after the originals? Good day.

BTW, thanks to the people that produced this vignette, it was nice and well done.

Murray Macdonald

March 15th, 2014 at 1:18 am

Brian. Dave posted a link to his company in my mind meeting the requirements of being honest, and thereby effectively mentions his company. He could have easily posted anonymously. I also think he asks a fair question.

Brandon Essex

January 27th, 2015 at 12:22 am

Dave Thomas has his product manufactured in CHINA??!!??

That does it. I will never eat a Jr. Bacon Cheeseburger again.

How do they keep it hot on the boat anyway??

(It’s a slow boat from China after all….)

Notforthistime

October 13th, 2017 at 5:14 am

Wel I like both arguments from expenses of factorys in Germany or China but dont be fooled how much money is used for marketing and research. I know this thread is old but still valeu of today.

Do understand like any company today has alot of unnecessary cost. Nueman does not need to spend million in marketing and turn up at every event. The name is already there and if sounds good the word goes around faster than you think. So whats cheap marketing go around to studio’s with a bunch of microphones yup.

Cheerio

Rishi

January 28th, 2018 at 8:28 am

Well, there is a reason that Neumann have a name that is ringing in every engineers ears. Their mikes “sound” – and they deliver “absolute” Quality (which you can judge quite well from the little clip). However, their products have a price that is comprised of legends, quality, research, experience, fair trade and treatment of their employees), excellent service, longevity and exclusivity. Like a Mercedes or any exclusive high quality brand (I’m not talking about blown up marketing hypes). The same is true for Schoeps and Sennheiser, AKG and the like…

And BTW: I think, they do have to spend millions on marketing and shows at fairs and expos because there’s where they meet their present and future customers and get new ideas for the demands of todays audio business.

On the other hand, it is of course possible to produce great quality and longlasting mikes for a more customer friendly price… But probably difficult without the use of Chinese facilities…

Dave Mack

April 23rd, 2019 at 4:10 pm

There is somewhat some hogwash in amongst it all.

Just like mobile phones, have you ever wondered how many grams of material are used in the construction of a phone ?

Not too many, and aside from the lack of material a consumer receives in exchange for more than $1,000.00, how many times over in future years is the consumer going to be expected to pay for the old cry of development technology..

As for the amount of employees kept alive and being fed by these good and decent life saving microphone companys.

Well, you can bet London to a brick, that the presice & modern automation

has many less employed than in days gone by and as hard as you may look you surely wont find one extra employed body than absolutely necessary, infact these wonderful feeding employer companys could more than likely curve the high work loads and employ several other bodys.

Be realistic, these companys are only geared around maximum profit margin as they are and as they have always been.

The consumer is paying far more than we should be paying in this day and age of technology.THIS IS THE REAL TRUTH.!.

ROLLOW ARLIN

December 7th, 2020 at 1:15 am

When you have an established name that is recognized as the best in it’s field and no one believes anyone else can match your quality? You can charge any amount the market will bare. You don’t need super hearing or a trained ear to hear the tiny bit extra costly mics add to the product but is that little more worth an extra thousand or two ? Face facts Neumann mics give recording studios bragging rights and if your in that business their a must have. I recently bought an expensive tube mic. A very top end unit for my home studio. In hind sight I now believe the money would have been better spent on a high quality tube preamp and a good quality non valve mic like a AT 4050. Too much emphasis is placed on the name. Someday someone will offer a better mic then Neumann makes but it won’t matter to anyone.