Granelli G5790, the right-angle SM57

Tuesday, June 9th, 2009 | by matthew mcglynn

The Shure SM57 is probably the most commonly used snare-drum and guitar-cab mic in history. It’s the go-to dynamic mic for all kinds of engineers, from name-brand guys in expensive studios to the high-school thrashers in the garage down the street. Hell, even Steve Albini has a couple (although judging from his comments there he doesn’t reach for them very often).

The Shure SM57 is probably the most commonly used snare-drum and guitar-cab mic in history. It’s the go-to dynamic mic for all kinds of engineers, from name-brand guys in expensive studios to the high-school thrashers in the garage down the street. Hell, even Steve Albini has a couple (although judging from his comments there he doesn’t reach for them very often).

But the mic is cursed by its size. It measures over 6'' long, and it needs to be pointed directly at whatever it’s supposed to hear. For a snare drum application this means the butt end is sticking up 6'' in the air — plus a couple more inches for the XLR jack of the mic cable — and it can be difficult to sandwich that into a tight drum kit setup.

I recently saw two solutions to this problem.

The low-tech approach is described in this Musformation.com story: The Bent Shure SM57 Trick. Duct tape plus a ’57… if McGuyver were an engineer, this would be his microphone. It will mike your snare drum, and afterwards can also somehow be used to blow the hinges off the studio bathroom door when the bassist passes out in the stall.

The low-tech approach is described in this Musformation.com story: The Bent Shure SM57 Trick. Duct tape plus a ’57… if McGuyver were an engineer, this would be his microphone. It will mike your snare drum, and afterwards can also somehow be used to blow the hinges off the studio bathroom door when the bassist passes out in the stall.

The slicker solution is a new product from Granelli Audio Labs. Founders Tony Correlli and John Grant have come up with a precision-machined 90° elbow that screws into an SM57 between the capsule end and the XLR end. They bill their G5790 as “The mic you’ve always loved — with the mod you’ve always needed.”

The slicker solution is a new product from Granelli Audio Labs. Founders Tony Correlli and John Grant have come up with a precision-machined 90° elbow that screws into an SM57 between the capsule end and the XLR end. They bill their G5790 as “The mic you’ve always loved — with the mod you’ve always needed.”

I love the idea of it, so I got in touch to ask about the backstory. Tony and John were gracious enough to send me the full history. Read on for the Birth of the Side-Address SM57!

Tony Correlli

John and I came up with the idea of a side-address SM57 while talking shop over the phone late one night a little over a year ago. Because the SM57 conveniently unscrews a couple of inches back from the capsule, John went out and found a PVC plumbing elbow at Home Depot, and had a friend fit it into an SM57. We miked up a snare and it sounded good against the stock 57, while being much easier to position. This was really a labor of love from two engineer/producer/musician guys who just wanted to make better records and make our workday more enjoyable.

Once we started using this first, kluged prototype on sessions we noticed that most of the drummers and fellow engineers who saw it wanted one. We then began searching for a way to make the part more solid, to keep the SM57 the tough workhorse that it is. After trying to cut and weld steel pipe with less-than-ideal results, we checked out a machine shop that said they could mill it out of a solid piece of aluminum to any specifications.

At the same time we were studying the original patent drawings for the SM57 and learning about the acoustic chamber within the handle of the mic. We already knew that opening the back of the mic changed the sound, so something was going on there that we needed to pay attention to.

We worked closely with a talented machinist to come up with a design that would seamlessly fit and would have some solid areas to keep the inside of the mic from growing too large. This produced the first metal prototype, and this is where the serious testing began. I clamped an SM57 down onto a board, fastened at a fixed distance from a studio monitor. Feeding the mic white noise, I tested the same mic without our prototype, with our prototype, with the internal chamber stuffed with material, and with the back of the mic unscrewed and hanging down.

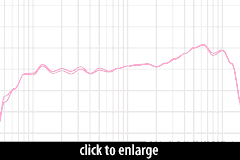

What we found was that our first prototype changed the frequency response up to 3dB at several frequencies compared to the factory version of the mic. It was then that we began to do all the math to determine the volume of the mic’s internal chamber with and without the part. With our prototype, the volume had nearly doubled, and figured this must be the reason for the frequency-response change.

One nagging concern remained — what if the sound is in the shape, not the volume? To test our air-volume hypothesis, we inserted a carefully measured piece of material that filled the excess space. When we ran the test again, we found that the curve was a closer match.

Knowing what we needed to do to make the part work, we had the machinist extend the male end of the piece to completely fill the mic’s chamber, and to reduce the size of the wiring passageway. After deducting the volume added by the wires and heat-shrink tubing, the volume of the mic fitted with the 2nd prototype would be the same as a factory SM57.

It was time for a test to determine if we had completely preserved the sonics of the SM57. Reproducing the first experiment, we mounted a mic, tested it unmodified, modified with our new part in, then with the 1st prototype with and without the added material, and even the PVC piece. I also tried another stock SM57 that was purchased at the same time.

What we found was that our 2nd prototype gave us identical results, sonically, to the stock 57. The slight variations were about as close as the frequency response of one factory SM57 compared with another. The previous prototype still had variations, especially without the material, and the original PVC version had the largest discrepancies, but the 2nd machined aluminum version was right on.

About this time we had a patent attorney file our application for a utility patent. We are currently in patent pending status. We also sent the mic to be independently tested by Arthur Sloatman of Midget Electronics in Nashville. He also concluded that the frequency responses were a match by testing an SM57 with and without the modification.

Make prototypes, listen to the results, and confirm them independently… that’s the way these things are supposed to go. Nice work, John and Tony.

Update, 2013: Shortly after the 2009 release of the G5790, Granelli Audio Labs began offering a DIY SM57 90° conversion kit. So, if like Steve Albini you have SM57s getting dusty already, and you don’t want to buy a new one that pushes the straight models even further back into the recesses of the mic cabinet, grab the Granelli kit and put those 57s back to work.

On the other hand, if you’re in the market for a new snare-drum mic and have been considering an SM57, do yourself a great big favor and buy the G5790 instead.

Tags: john grant, steve albini, tony correlli

Posted in Microphones | 1 Comment »

Jon

August 10th, 2009 at 7:39 pm

It looks like Granelli is offering the part for DIY-ers – http://www.granelliaudiolabs.com/part.html